- + 91-9167662789

- care@dktee.com

June 20, 2023

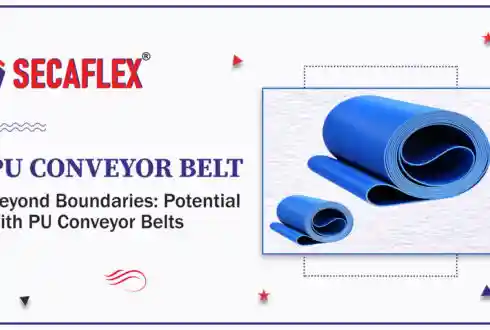

Conveyor belts are an essential component of industrial automation, since they play an important part in the process of simplifying operations and guaranteeing effective material handling. Polyurethane (PU) conveyor belts have emerged as a game-changer among the many other varieties of conveyor belts that are now on the market.

These belts provide advantages that are unmatched in terms of their durability, adaptability, and performance. This article digs into the intriguing world of PU Conveyor Belt and investigates how these belts are releasing the potential to revolutionise businesses all around the world.

Durability

They are recognised for their remarkable durability, which makes them perfect for applications that entail large loads, high-speed operations, and abrasive materials. Because of their exceptional durability, these belts have been more popular in recent years. They in contrast to typical conveyor belts, have a remarkable resistance to wear and tear, which ensures that their service life will be extended even in tough situations. As a result of this durability, downtime and maintenance costs are cut significantly, which in turn leads to a rise in both productivity and operational efficiency.

Adaptability

One of the most notable characteristics of them is its adaptability, which allows for a high level of customization. These belts may be modified to fulfil the special needs of a variety of different sectors, including the food processing industry, the automobile industry, the packaging industry, and others. PU belts are offered in a wide variety of configurations, which may include a variety of surface textures, colours, and degrees of hardness.

This gives companies the ability to choose the PU belt that is most suited for the applications they run. In addition, PU Conveyor Belt may be customised with specialised attributes like as anti-static capabilities, low-friction coatings, and improved grip, which further expands the variety of applications for which they can be used.

Enhanced Performance

They provide remarkable performance qualities, which contribute to better production and operational efficiency. The low-friction surface of PU belts allows for the smooth and efficient movement of items, which in turn reduces the amount of energy used and the amount of product damage that occurs.

In addition, the exact and regular thickness of PU belts by PVC Conveyor Belt Manufacturers in India guarantees correct product placement and alignment, which is absolutely necessary for automated assembly processes. Because of their high-strength design, PU belts are capable of handling big loads and withstanding high-speed operations. This makes them a perfect option for industries that need maximum performance from their products.

Hygiene and Food Safety

It is of the utmost importance to maintain rigorously high hygiene and food safety standards in some fields, such as the food processing and pharmaceutical sectors. Conveyor belts made of polyurethane (PU) are constructed using materials that are in accordance with severe hygiene rules, such as those governing food contact in the EU and FDA.

The smooth and non-porous surface of PU belts avoids the buildup of dirt and makes it easier to clean, hence lowering the likelihood that the belts will get contaminated. Because of these characteristics, PU belts are an excellent choice for use in sectors where maintaining a sanitary environment and the quality of products is of the highest significance.

Reducing Noise and Improving Energy Efficiency

Conventional conveyor belts may produce a large amount of noise while in operation, which can cause discomfort for employees as well as possible health problems. PU Conveyor Belt is meant to reduce the amount of noise produced, making for a calmer and more pleasant working atmosphere. In addition, the low-friction characteristics of PU belts help to minimise energy consumption, which results in cost savings and contributes to the sustainability of the environment.

Conclusion

Conveyor belts made of polyurethane have been shown to be a game-changing breakthrough, which has unlocked enormous possibilities across a variety of business sectors. PU belts are changing material handling operations because to their increased durability, adaptability, better performance, and compliance with hygiene regulations.

Conveyor belts made of polyurethane (PU) are becoming an increasingly popular option as organisations continue to look for ways to increase their efficiency and production. This choice enables businesses to conduct smooth operations that extend beyond their typical bounds. When it comes to the domain of industrial automation, realising the potential of polyurethane (PU) belts may unlock a world of unfathomable possibilities.

DKT Engineering Enterprises is the leading PVC Conveyor Belt Suppliers in India. The company has made great effort in the past ten years, and has achieved great improvements in the performance and reliability areas.

DKT Engineering Enterprises

DKT Engineering Enterprises has vast experience in manufacturing conveyor belts in India. We are providing high quality products to our clients Since 2010.