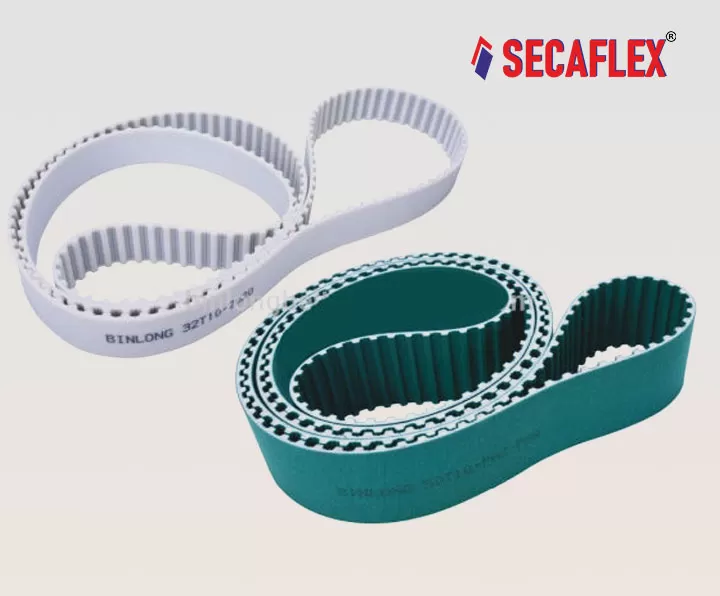

We are one of the top PU Timing Belt Suppliers In India, and thus, we possess a wide range of timing belt options to choose from. Our PU Timing Belt gets well recognised for its outstanding quality. These belts are in great demand because of their increased efficiency and transmission speeds. We provide our products to a wide range of businesses throughout industries and are also quite successful in doing so.

At our manufacturing facility, we use advanced machinery to manufacture high-quality resin bodies and a steel grip cord for each of our timing belts. To further reduce bearing stress and improve belt length uniformity, we infuse high modulus cords in these belts. In addition, we combine premium materials and cutting-edge technologies to appropriately package our items so that they can endure the hardships of shipping, handling, and mechanical damages.

The operating temperature range for these belts is between -30 to 100 degrees Fahrenheit. In addition, both the top and bottom surfaces are coated with polyurethane to provide high wear resistance and excellent operating capabilities. Since our belts come with these many attributes, they have huge demand in markets. Also, you can avail our timing belts at cost-competitive prices.