- + 91-9167662789

- care@dktee.com

March 14, 2023

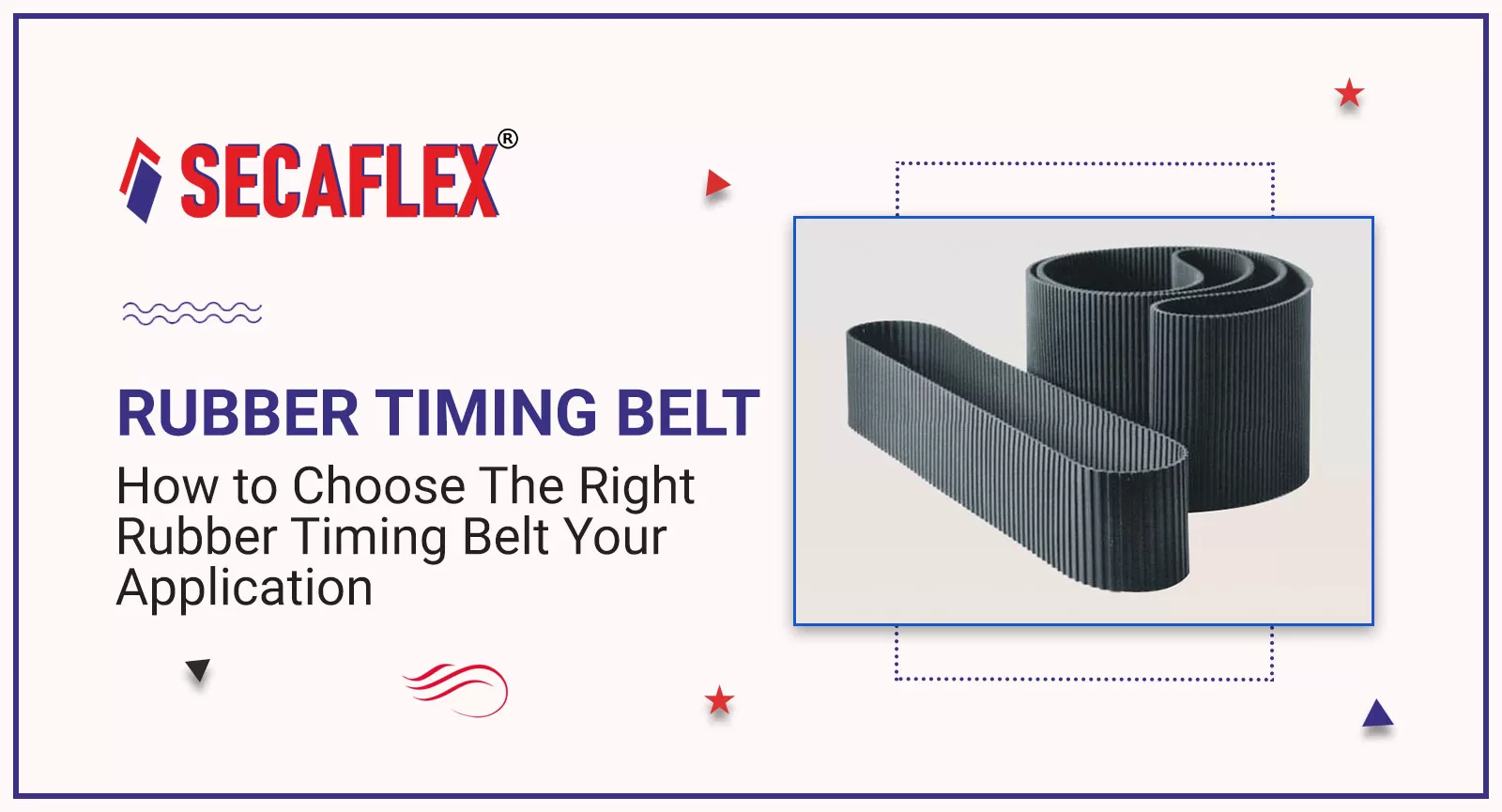

Rubber Timing Belts are essential components in various industrial and automotive applications. These belts are designed to synchronize the rotation of engine components, allowing them to operate in harmony and improve performance. However, choosing the right rubber belt can be a daunting task, especially with the numerous available options

Key factors to consider when choosing the right rubber timing belt for your application

Belt Profile:

The first consideration when choosing a rubber belt from Rubber Timing Belt Manufacturers in India is the profile of the belt. There are two primary profiles to choose from – trapezoidal and curvilinear. Trapezoidal belts have a trapezoidal tooth profile and are commonly used in industrial applications. Curvilinear belts have a rounded tooth profile and are more commonly used in automotive applications. It’s essential to choose a belt profile that matches the requirements of your application to ensure optimal performance.

Belt Width:

The width of the rubber belt is another crucial factor to consider. The width of the belt determines the amount of power it can transmit. A wider belt can transmit more power than a narrower belt. However, wider belts may require more tension, increasing wear, and tear. It’s essential to choose a belt width that matches the power requirements of your application while balancing the tension requirements.

Pitch of the Rubber:

The pitch of a rubber belt refers to the distance between the center of two adjacent teeth. The belt’s pitch is essential in determining the belt’s compatibility with other components, such as pulleys. It’s essential to choose a belt with a pitch that matches the pitch of the pulleys and other components in your application.

Rubber Material

The material used to make the belt is critical in determining its durability and performance. Most belts are made of synthetic rubber, which can withstand high temperatures and pressures. However, the quality of the rubber can vary, and it’s essential to choose a belt made of high-quality synthetic rubber to ensure optimal performance and durability.

Tensioning System

The tensioning system used in your application can also influence the type of belt to choose. Two primary tensioning systems are used in belts – automatic and manual tensioning. Automatic tensioning systems are ideal for applications that require constant tension, such as high-speed applications. Manual tensioning systems are more suitable for low-speed applications and applications where the tension requirements may vary.

Environmental Factors

The environmental factors in your application can also influence the type of belt to choose. For instance, if your application operates in a dusty or humid environment, you may need to choose a belt with higher resistance to dust and moisture. Additionally, if your application operates in extreme temperatures, you may need to choose a belt that can withstand high temperatures without losing its elasticity.

Belt Life

The expected belt life is another crucial factor when choosing a belt. Various factors, such as the quality of the belt, the tension requirements, and the environmental factors, determine the belt’s life. Choosing a belt with a long life is essential to reduce the frequency of belt replacements and downtime.

Conclusion:

Choosing the right rubber timing belt is critical to the performance and durability of your application. When selecting a belt, it’s essential to consider factors such as the belt profile, width, pitch, material, tensioning system, environmental factors, and expected belt life. By considering these factors, you can choose a belt that matches the requirements of your application and ensures optimal performance and durability. When it comes to looking for the best Rubber Timing Belt Suppliers in India, then DKT Engineering Enterprises is the ideal option.

DKT Engineering Enterprises

DKT Engineering Enterprises has vast experience in manufacturing conveyor belts in India. We are providing high quality products to our clients Since 2010.